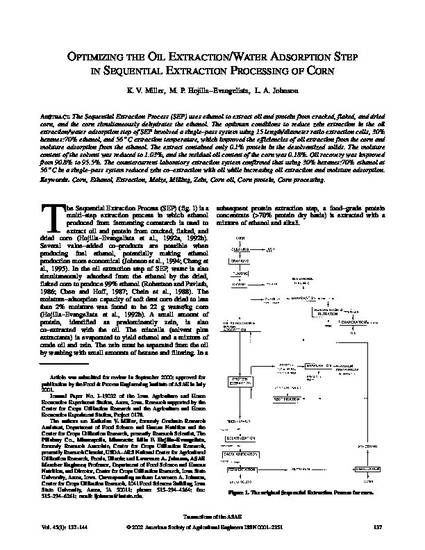

The Sequential Extraction Process (SEP) uses ethanol to extract oil and protein from cracked, flaked, and dried corn, and the corn simultaneously dehydrates the ethanol. The optimum conditions to reduce zein extraction in the oil extraction/water adsorption step of SEP involved a single–pass system using 15 length/diameter ratio extraction cells, 30% hexanes: 70% ethanol, and 56C extraction temperature, which improved the efficiencies of oil extraction from the corn and moisture adsorption from the ethanol. The extract contained only 0.1% protein in the desolventized solids. The moisture content of the solvent was reduced to 1.03%, and the residual oil content of the corn was 0.18%. Oil recovery was improved from 90.8% to 95.5%. The countercurrent laboratory extraction system confirmed that using 30% hexanes:70% ethanol at 56C in a single–pass system reduced zein co–extraction with oil while increasing oil extraction and moisture adsorption.

Available at: http://works.bepress.com/lawrence_johnson/40/

This article is from Transaction ASAE 45(1) 2001: 137-144. doi: 10.13031/2013.7856. Posted with permission.