Article

Thermal Conductivity of Protein-Based Materials: A Review

Polymers

(2019)

Abstract

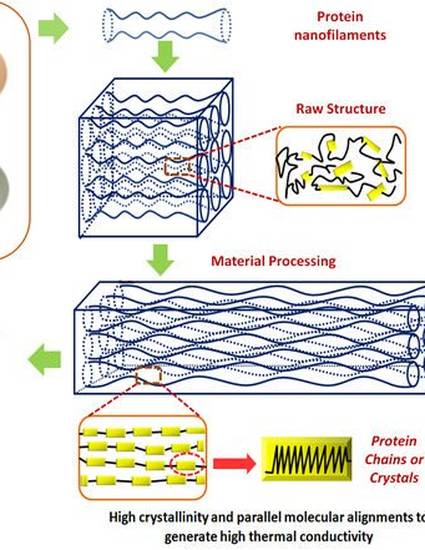

Fibrous proteins such as silks have been used as textile and biomedical materials for decades due to their natural abundance, high flexibility, biocompatibility, and excellent mechanical properties. In addition, they also can avoid many problems related to traditional materials such as toxic chemical residues or brittleness. With the fast development of cutting-edge flexible materials and bioelectronics processing technologies, the market for biocompatible materials with extremely high or low thermal conductivity is growing rapidly. The thermal conductivity of protein films, which is usually on the order of 0.1 W/m·K, can be rather tunable as the value for stretched protein fibers can be substantially larger, outperforming that of many synthetic polymer materials. These findings indicate that the thermal conductivity and the heat transfer direction of protein-based materials can be finely controlled by manipulating their nano-scale structures. This review will focus on the structure of different fibrous proteins, such as silks, collagen and keratin, summarizing factors that can influence the thermal conductivity of protein-based materials and the different experimental methods used to measure their heat transfer properties.

Keywords

- thermal conductivity,

- protein,

- crystal structure,

- green materials

Disciplines

Publication Date

March 11, 2019

DOI

https://doi.org/10.3390/polym11030456

Publisher Statement

This is an open access article distributed under the Creative Commons Attribution License which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Citation Information

Ye Xue, Samuel E. Lofland and Xiao Hu. "Thermal Conductivity of Protein-Based Materials: A Review" Polymers Vol. 11 Iss. 3 (2019) p. 456 Available at: http://works.bepress.com/samuel-lofland/22/