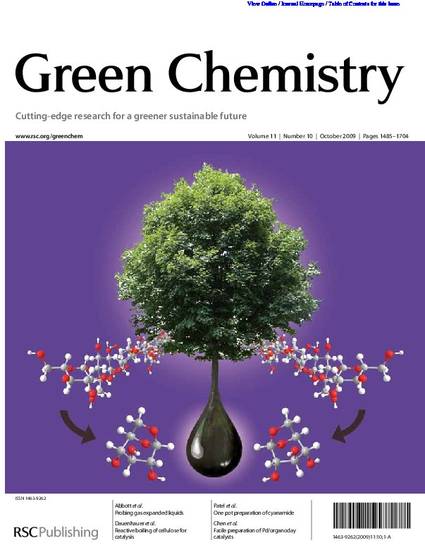

Advanced biomass processing technology integrating fast pyrolysis and inorganic catalysis requires an improved understanding of the thermal decomposition of biopolymers in contact with porous catalytic surfaces. High speed photography (1000 frames per second) reveals that direct impingement of microcrystalline cellulose particles (300 μm) with rhodium-based reforming catalysts at high temperature (700 °C) produces an intermediate liquid phase that reactively boils to vapors. The intermediate liquid maintains contact with the porous surface permitting high heat transfer (MW m−2) generating an internal thermal gradient visible within the particle as a propagating wave of solid to liquid conversion. Complete conversion to liquid yields a fluid droplet on the catalyst surface exhibiting a linear decrease in droplet volume with time leaving behind a clean surface absent of solid residue (char). Under specific interfacial conditions, conversion with large cellulosic particles on the length-scale of wood chips (millimeters) occurs continuously as generated liquid and vapors are pushed into the porous surface.

Available at: http://works.bepress.com/paul_dauenhauer/2/