Presentation

Thermal Fluid Model Development of Steam Methane Reformer using Artificial Neural Network

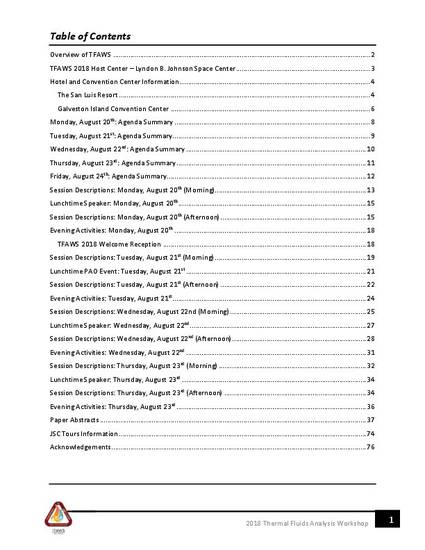

2018 Thermal Fluids Analysis Workshop

(2018)

Abstract

NASA’s Johnson Space Center has recently begun efforts to eventually integrate air-independent Solid Oxide Fuel Cell systems, with landers that can be propelled by LOX-CH4, for long duration missions. Using landers that utilize such propellants, provides the opportunity to use such systems as a power option, especially since they are able to process methane into a reactant through fuel reformation. To ensure fuel reformation in the systems, Steam Methane Reformation (SMR) are being employed. Various lead-up activities, such as hardware testing and computational modelling, have been initiated to assist with this developmental effort. One modeling approach, currently being explored to predict SMR thermal fluid dynamic behavior, involves the usage of artificial neural networks (ANN). Since SMR thermal fluid performance characteristics are inherently complex, ANN can account for such nonlinear characteristics of multiple input and output variables to better predict its performance. There are minimal to no studies on the development of dynamic ANN to predict the transient behavior of SMR in the way that this modeling work investigates. The work to be presented involves prediction of the dynamic performance of a SMR tube reactor at operating conditions including temperatures around 600-700oC and pressures around 5 psig. In this work, six input variables being considered consist of steam and methane inlet temperatures, pressures, and flow rates. The output variables that represent the thermal fluid behavior are SMR outlet temperature and pressure. The compositions in the inlet and outlet flow rates of SMR will be considered in a future presentation. The dynamic temperature and pressure models of two different ANN structures (time delay only, and time delay and NARX) are judged based on accuracy and consistency. To develop an optimal ANN model, the number of hidden layer neurons is varied from 1 to 25. The model responses (> 10 hidden neurons) were demonstrated to predict the experimental data very well. The coefficient of determinations of all models ranged from 0.97 to 1. For temperature response, the ANN models with NARX and time delay predicts better with MSE from 0.1 to 0.4 than the ANN models with time delay only with lowest MSE of 22. For pressure, the ANN models with NARX and time delay predict slightly to almost negligibly better with MSE from 0.03 to 0.07 than the ANN models with time delay only, which also has similar MSE from 0.03 to 0.08. This could be due to the higher fluctuations in the SMR pressure data. The results show promise of ANN modeling approaches for offline and real-time prediction of transient thermal fluid behavior to assist in the system integration of SMR into the power source of the lander.

Disciplines

Publication Date

Fall August, 2018

Citation Information

M. A. Rafe Biswas. "Thermal Fluid Model Development of Steam Methane Reformer using Artificial Neural Network" 2018 Thermal Fluids Analysis Workshop (2018) Available at: http://works.bepress.com/mohammad-biswas/24/