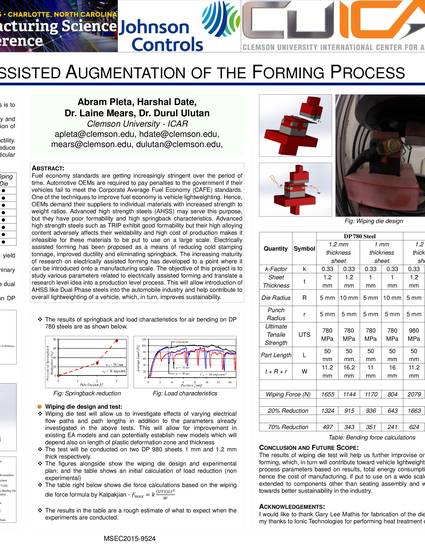

Fuel economy standards are getting increasingly stringent over time. Automotive OEMs are required to pay penalties to the government if their vehicles fail to meet the CAFE standards. One of the techniques to improve fuel economy is vehicle lightweighting. Hence, OEMs demand their suppliers to individual materials with increased strength to weight ratios. Advanced high strength steels (AHSS) may serve this purpose, but they have poor formability and high springback characteristics. Advanced high strength steels such as TRIP exhibit good formability but their high alloying content adversely affects their weldability and high cost of production makes it infeasible for these materials to be put to use on a large scale. Electrically assisted forming has been proposed as a means of reducing cold stamping tonnage, improved ductility and eliminating springback. The increasing maturity of research on EAF has developed to a point where it can be introduced onto a manufacturing scale. The objective of this project is to study various parameters related to electrically assisted forming and translate a research level idea into a production level process. This will allow introduction of AHSS like Dual Phase steels into the automobile industry and help contribute to overall lightweighting of a vehicle.

Available at: http://works.bepress.com/m_mears/6/