Faced with limited financial resources, pavement engineers constantly seek more durable and economical technologies for road preservations and rehabilitations. Consequently, there have been many efforts to study resurfacing strategies, including various types of sealing for local roads. Among different sealing methodologies, Otta seal is a technique that has not yet been sufficiently studied in the U.S.A. For this investigation, the first Otta seal site in the state of Iowa was constructed using a double-layer Otta seal design over 6.4 km of cracked asphalt pavement. Otta seal design and construction details are documented and discussed, and test sections using various aggregates are compared for performance. The key lesson learned was that proper aggregate selection within gradation limits and aggregate spread rates were critical factors for Otta seal performance. Otta seal capability for holding loose aggregate particles and for dust control were examined, and there were indications that excessive proportion of fine aggregate particles could lead to diminished performance associated with fugitive dust emissions and unbound aggregate particles. Although the Otta seal provided a smooth surface satisfying road user and agency requirements, it did not significantly add structural capacity to the existing asphalt pavement. The findings from this study will benefit road officials and other decision makers who need to consider alternatives for resurfacing distressed low-volume asphalt roads.

Low-volume roads represent a large proportion of the route mileage of the transportation infrastructure system, and the cost to secondary road departments of maintaining such roads can be quite important. Over time, Otta seal has exhibited reduced maintenance costs by providing a typical service life of 8 to 12 years for a single-layer Otta seal, compared with 4 to 6 years for single-layer chip seal (1–3).

Norway-based Otta seal (graded aggregate) technology, originally developed in the 1960s and used in Scandinavian countries, Africa, and other continents, is an economical and practical alternative to traditional bituminous surface treatments (BSTs). It provides flexible, durable, and impervious surfacing that is more tolerant of higher anticipated pavement deflections on low-volume roads that are sometimes constructed with lower-quality materials (4). Compared with traditional BSTs requiring high-quality materials and specialized expertise, Otta seal can often be constructed using more economical local aggregates and readily available equipment (asphalt distributor, aggregate spreader, pneumatic-tired roller, and mechanical broom) typically used for asphalt maintenance (4). Otta seal, formed by a thin bituminous surface treatment (BST) of graded aggregates, ranging from natural gravel to crushed stone, with a relatively low-viscosity binder, relies on a combination of mechanical particle interlock and the binding effect of asphalt binder to provide a resilient, waterproof membrane over the road surface.

The state of South Dakota completed its first Otta seal project in Day County in 2008 to provide a low-cost surface using in-house resources and equipment in place of a standard hot-mix asphalt (HMA) pavement surface (5). Various agencies (city, county, and state department of transportation) in Minnesota have also applied Otta seal for traffic volumes ranging from 100 up to 2,000 vehicles average daily traffic (ADT) since early 2000 (6, 7). Most road sections surfaced with Otta seal in Minnesota have performed well except when they encountered unexpected situations such as unanticipated high traffic volumes or flood damage during their service lives (7). Otta seal construction was also found reasonably affordable compared with HMA or Portland cement concrete (PCC) pavement systems for use on low-volume roads; Otta seal has been considered a cost-effective and durable approach to dust control for gravel roads. In particular for developing countries, the available evidence suggests that Otta seal, surface dressings, and Cape seal are the most cost-effective and durable forms of dust control in relation to life-cycle costs (8–10).

The Norwegian Public Roads Administration (NPRA) Guideline 93 (4) was compiled using empirical data and experience from many trials and full-scale projects worldwide. However, in the U.S.A., few states have used the Otta seal, and hence, it is felt that a more comprehensive research along with full documentation is necessary to assist in the implementation of Otta seals in Iowa and many other states in the U.S.A.

Available at: http://works.bepress.com/halil_ceylan/329/

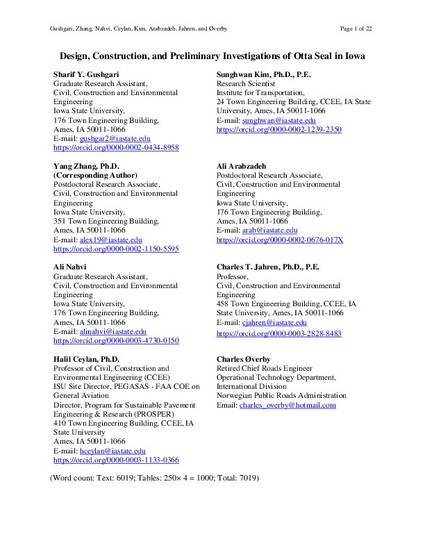

This is a manuscript of an article published as Gushgari, Sharif Y., Yang Zhang, Ali Nahvi, Halil Ceylan, Sunghwan Kim, Ali Arabzadeh, Charles T. Jahren, and Charles Øverby. "Design, Construction, and Preliminary Investigations of Otta Seal in Iowa." Transportation Research Record (2019). DOI: 10.1177%2F0361198119853567. Posted with permission.