Article

Statistically-Based Pattern Approval Process

AFS Transactions

(1996)

Abstract

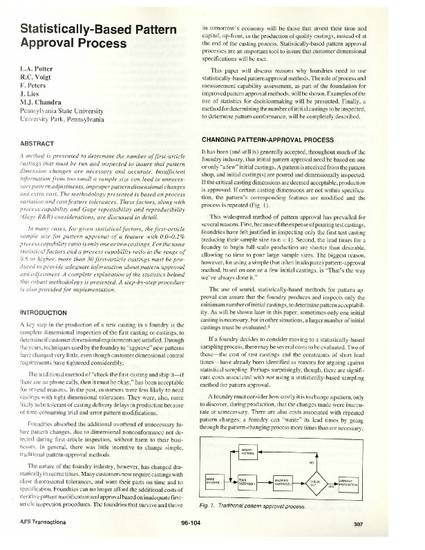

A method is presented to determine the number of first-article castings that must be run and inspected to insure that pattern dimension changes are necessary and accurate. Insufficient information from too small a sample from too small a sample size can lead to unnecessary pattern adjustments, improper pattern dimensional changes and extra cost. The methodology presented is based on process variation and cast feature tolerances. These factors, along with process capability and Gage repeatability and reproducibility (Gage R&R) considerations, are discussed in detail.

In many cases, for given statistical factors, the first-article sample size for pattern approval of a feature with 0.0-0.2% process capability ratio in the range of 0.6 or higher, more than 30 first-article castings must be produced to provide adequate information about pattern approval and adjustment. A complete explanation of the statistics behind this robust methodology is presented. A step-by-step procedure is also provided for implementation.

Disciplines

Publication Date

1996

Publisher Statement

Copyright American Foundry Society 1996

Citation Information

L.A. Potter, R.C. Voigt, Frank E. Peters and J. Lies. "Statistically-Based Pattern Approval Process" AFS Transactions Vol. 104 (1996) p. 307 - 316 Available at: http://works.bepress.com/frank_peters/15/