Article

The Impact of Surface Errors on the Location and Orientation of a Cylindrical Workpiece in a Fixture

Journal of Manufacturing Science and Engineering, Transactions of the ASME

Document Type

Article

Disciplines

Publication Version

Published Version

Publication Date

5-1-2001

DOI

10.1115/1.1367269

Abstract

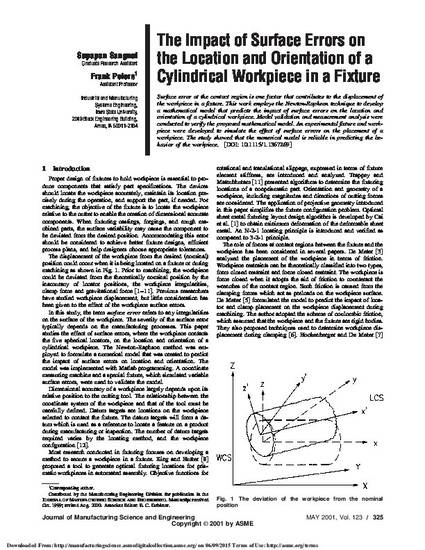

Surface error at the contact region is one factor that contributes to the displacement of the workpiece in a fixture. This work employs the Newton-Raphson technique to develop a mathematical model that predicts the impact of surface errors on the location and orientation of a cylindrical workpiece. Model validation and measurement analysis were conducted to verify the proposed mathematical model. An experimental fixture and workpiece were developed to simulate the effect of surface errors on the placement of a workpiece. The study showed that the numerical model is reliable in predicting the behavior of the workpiece.

Copyright Owner

ASME

Copyright Date

2001

Language

en

File Format

application/pdf

Citation Information

Supapan Sangnui and Frank E. Peters. "The Impact of Surface Errors on the Location and Orientation of a Cylindrical Workpiece in a Fixture" Journal of Manufacturing Science and Engineering, Transactions of the ASME Vol. 123 Iss. 2 (2001) p. 325 - 330 Available at: http://works.bepress.com/frank_peters/1/

This article is from Journal of Manufacturing Science and Engineering, Transactions of the ASME 123 (2001): 325, doi: 10.1115/1.1367269. Posted with permission.