Article

Optimization of a New In-bin Counterflow Corn Drying System

Transactions of the ASAE

(1993)

Abstract

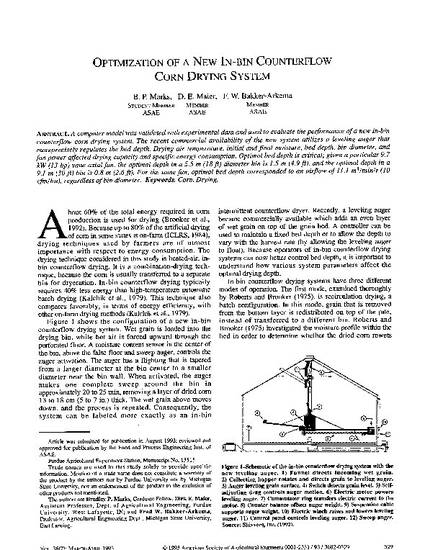

A computer model was validated with experimental data and used to evaluate the performance of a new in-bin counterflow corn drying system. The recent commercial availability of the new system utilizes a leveling auger that moreprecisely regulates the bed depth. Drying air temperature, initial and final moisture, bed depth, bin diameter, and fan power affected drying capacity and specific energy consumption. Optimal bed depth is critical; given a particular 9.7 kW (13 hp) vane-axial fan, the optimal depth in a 5.5 m (18 ft) diameter bin is 1.5 m (4.9 ft), and the optimal depth in a 9.1 m (30 ft) bin is 0.8 m (2.6 ft). For the same fan, optimal bed depth corresponded to an airflow of 11.1 m3/min/t (10 cfm/bu), regardless of bin diameter.

Keywords

- Corn,

- Drying

Disciplines

Publication Date

1993

DOI

10.13031/2013.28369

Publisher Statement

Copyright 1993 American Society of Agricultural and Biological Engineers. Used with permission.

Citation Information

Bradley P. Marks, Dirk E. Maier and Fred W. Bakker-Arkema. "Optimization of a New In-bin Counterflow Corn Drying System" Transactions of the ASAE Vol. 36 Iss. 2 (1993) p. 529 - 534 ISSN: 0001-2351 Available at: http://works.bepress.com/dirk-maier/19/