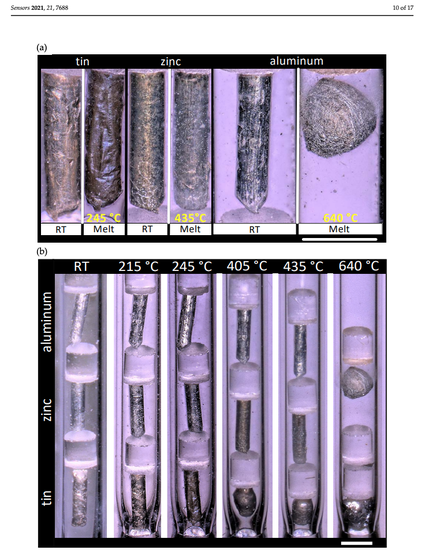

Passive monitoring techniques have been used for peak temperature measurements during irradiation tests by exploiting the melting point of well-characterized materials. Recent efforts to expand the capabilities of such peak temperature detection instrumentation include the development and testing of additively manufactured (AM) melt wires. In an effort to demonstrate and benchmark the performance and reliability of AM melt wires, we conducted a study to compare prototypical standard melt wires to an AM melt wire capsule, composed of printed aluminum, zinc, and tin melt wires. The lowest melting-point material used was Sn, with a melting point of approximately 230 °C, Zn melts at approximately 420 °C, and the high melting-point material was aluminum, with an approximate melting point of 660 °C. Through differential scanning calorimetry and furnace testing we show that the performance of our AM melt wire capsule was consistent with that of the standard melt-wire capsule, highlighting a path towards miniaturized peak-temperature sensors for in-pile sensor applications.

For a complete list of authors, please see the article.