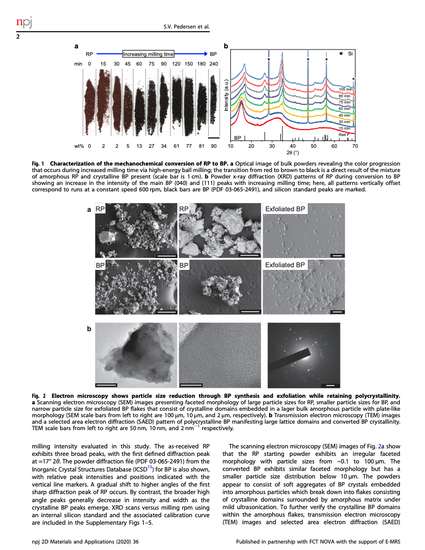

Adopting black phosphorus (BP) as a material in electronic and optoelectronic device manufacturing requires the development and understanding of a large-scale synthesis technique. To that end, high-energy planetary ball milling is demonstrated as a scalable synthesis route, and the mechanisms and conversion kinetics of the BP phase transformation are investigated. During the milling process, media collisions rapidly compress amorphous red phosphorus (RP) into crystalline, orthorhombic BP flakes, resulting in a conversion yield of ≈90% for ≈5 g of bulk BP powder. Milling conversion kinetics, monitored via ex situ x-ray diffraction, manifest a sigmoidal behavior best described by the Avrami rate model with each impact of sufficient energy (>25 mJ) producing BP nuclei; the process appears to be limited by grain growth. Using a kinematic model for ball trajectories and impact energies, the optimum milling condition is determined to be an impact energy near ≈25 mJ and a milling dose near ≈100 kJ/gram. Photoexcitation of exfoliated BP flakes reveals emission in the near-infrared, indicating the formation of few-layer BP, a promising advance for optoelectronic device applications.